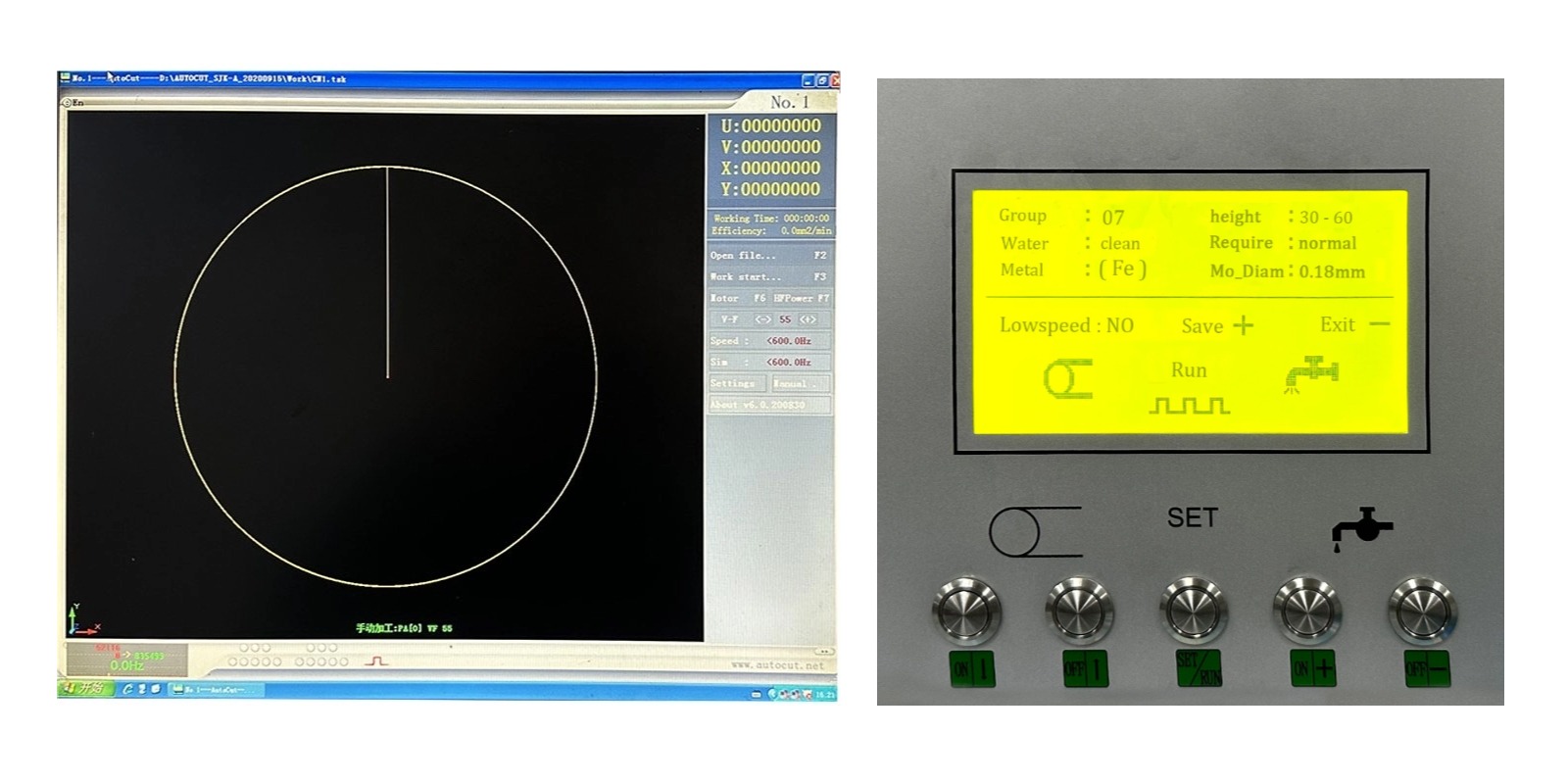

1. Autocut system 2. Smart database

3.Servo motor 4.Remote control box

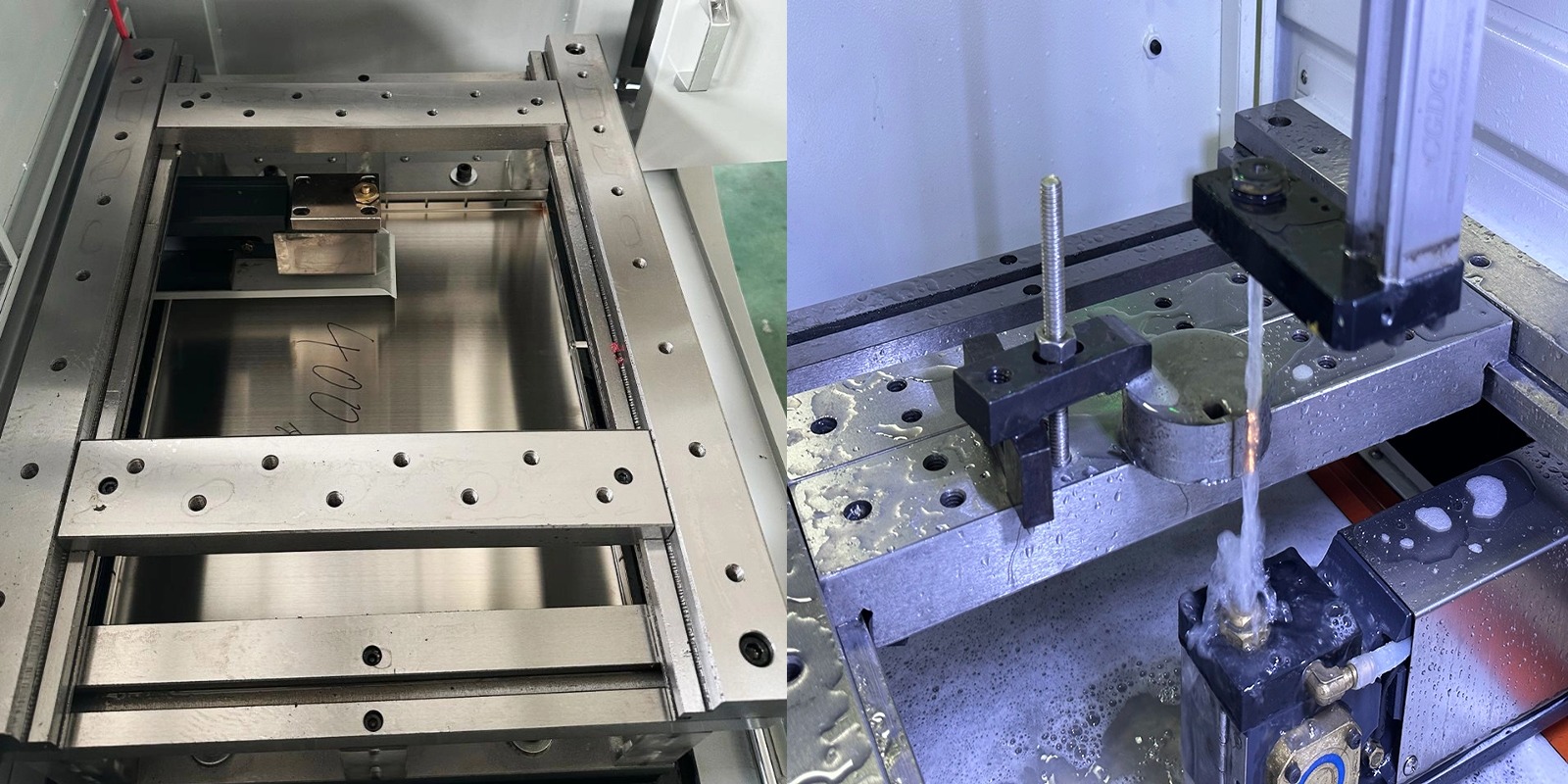

5.Double filter 150L water tank

6.After heat treatment, the fixture of the workbench ensures long-term wear resistance

and no deformation.

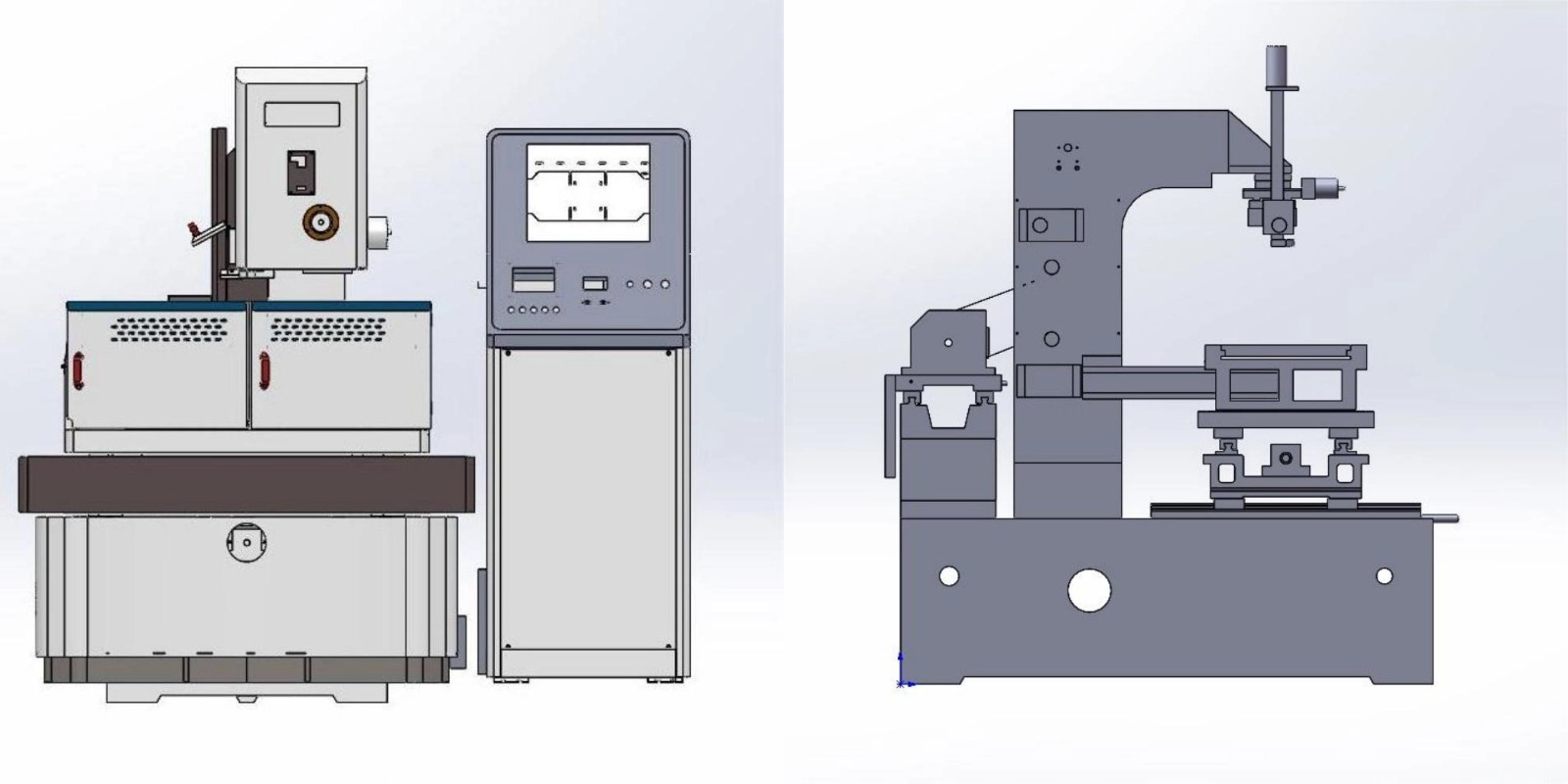

7.The mechanical structure and appearance are original designs, which have been rationalized,

improved and optimized.

Item | Unit | MY400 | MY500 |

Worktable size | mm | 600*460 | 720*530 |

CNC axis travel(X*Y) | mm | 400*320 | 500*400 |

U/V travel | mm | 32 | 32 |

Z travel | mm | 250 | 250 |

Max. cutting workpiece thickness | mm | 280 | 280 |

Max cutting taper | ±6°/80mm | ±6°/80mm | |

Max workpiece weight | kg | 400 | 500 |

Molybdenum wire diameter | mm | φ0.18 | φ0.18 |

Cutting accuracy | mm | ≤±0.005Φ20mm H=30mm(multiple cutting) | ≤±0.005Φ20mm H=30mm(multiple cutting) |

Surface roughness | μm | Ra≤0.8 | Ra≤0.8 |

Cutting efficiency | mm2/hr | 8000~12000 | 8000~12000 |

Power consumption | ≤3Kw 2-phase 220V/ 3-phase380V | ≤3Kw 2-phase220V/ 3-phase380V | |

Machine dimension | mm | 1800*1200*1950 | 1900*1300*1950 |

Cabinet size | mm | 850*680*1760 | 850*680*1760 |

Tank size | mm | 1030*660*860 | 1030*660*860 |

Machine weight | kg | ≈1600 | ≈1800 |

Motor Controller | XY servo motor UV stepper motor | XY servo motor UV stepper motor | |

Z axis lift type | Auto-lift | Auto-lift | |

X/Y axis type | Auto-manual | Auto-manual | |

Controlled axis | 4-axises | 4-axises | |

Lead screw/Guide type | Ball screw/Linear guide (made in Taiwan/ Germany) | Ball screw/Linear guide (made in Taiwan/ Germany) | |

Control system | Autocut | Autocut | |

Tanker | L | 150 | 150 |

Filter type | 3nd filtration | 3nd filtration | |

Min. Moving unit | mm | 0.001 | 0.001 |

Molybdenum wire tensioning device | √ | √ | |

Table waterproof cover | √ | √ | |

DRO | √ | √ | |

Aluminum Cutting Device | √ | √ |

Question: Are you a manufacturer or a distributor?

Answer: We are manufacturers. Welcome to visit our factory.

Question: How to choose the machine I want?

Answer: First of all, please match the worktable stroke and cutting thickness according to the size of the workpiece to find the appropriate model. Secondly,

please check whether the accuracy and roughness meet your requirements.

Question: The voltage in our country is three-phase 220V (or single-phase 220V, or other voltages), and the voltage of the machine is three-phase 380V. Can you change the voltage?

Answer: Yes. Please tell me the voltage you need and we will change it.

Question: If I purchase your machine, how can I obtain technical support?

Answer: We have detailed teaching videos. Even beginners can operate by watching the videos. Please search "Miyang Machine" on Facebook. Watch more videos!

Question: How is the after-sales service?

Answer: Damaged parts will be replaced free of charge during the warranty period. After the warranty period, they will be replaced at cost price. If you have any questions,

we will quickly provide you with solutions by shooting videos or other means.

Address

Tel

website

We will contact you within 24 hours. ( WhatsApp/facebook:)