Item | Unit | DK7745 DK7745-S | DK7745F DK7745F-S | DK7750 DK7750-S | DK7750F DK7750F-S | DK7763 DK7763-S | DK7763F DK7763F-S |

Worktable size | mm | 710*570 | 750*570 | 800*650 | 950*650 | 950*750 | 1150*750 |

CNC axis travel(X×Y) | mm | 550*450 | 650*450 | 630*500 | 800*500 | 800*630 | 1000*630 |

U/V travel | mm | 30 | 30 | 30 | 30 | 30 | 30 |

Max. cutting workpiece thickness | mm | 450 | 450 | 500 | 500 | 600 | 600 |

Max cutting taper | ±6°/80mm | ±6°/80mm | ±6°/80mm | ±6°/80mm | ±6°/80mm | ±6°/80mm | |

Max workpiece weight | kg | 500 | 500 | 700 | 700 | 1200 | 1200 |

Molybdenum wire diameter | mm | φ0.18 | φ0.18 | φ0.18 | φ0.18 | φ0.18 | φ0.18 |

Cutting accuracy | mm | ≤0.01(φ20mm,H=40mm) | ≤0.01(φ20mm,H=40mm) | ≤0.01(φ20mm,H=40mm) | ≤0.01(φ20mm,H=40mm) | ≤0.01(φ20mm,H=40mm) | ≤0.01(φ20mm,H=40mm) |

Surface roughness | μm | Ra≤1.2-2.0(multiple cutting) | Ra≤1.2-2.0(multiple cutting) | Ra≤1.2-2.0(multiple cutting) | Ra≤1.2-2.0(multiple cutting) | Ra≤1.2-2.0(multiple cutting) | Ra≤1.2-2.0(multiple cutting) |

Cutting efficiency | mm2/hr | 8000-15000 | 8000-15000 | 8000-15000 | 8000-15000 | 8000-15000 | 8000-15000 |

Power consumption | ≤2Kw AC 2-phase 220V | ≤2Kw AC 2-phase 220V | ≤2Kw AC 2-phase 220V | ≤2Kw AC 2-phase 220V | ≤2Kw AC 2-phase 220V | ≤2Kw AC 2-phase 220V | |

Machine dimension | mm | 1800*1480*1700 | 1800*1620*1700 | 2100*1760*1900 | 2100*1900*1900 | 2250*2250*1950 | 2250*2450*1950 |

Machine weight | kg | ≈1400 | ≈1400 | ≈1700 | ≈1700 | ≈1900 | ≈2200 |

Motor Controller | Stepper motor/ Servo motor | Stepper motor/ Servo motor | Stepper motor/ Servo motor | Stepper motor/ Servo motor | Stepper motor/ Servo motor | Stepper motor/ Servo motor | |

Z axis lift type | Auto-lift | Auto-lift | Auto-lift | Auto-lift | Auto-lift | Auto-lift | |

Controlled axis | 4-axises | 4-axises | 4-axises | 4-axises | 4-axises | 4-axises | |

Guide type | Linear guide | Linear guide | Linear guide | Linear guide | Linear guide | Linear guide | |

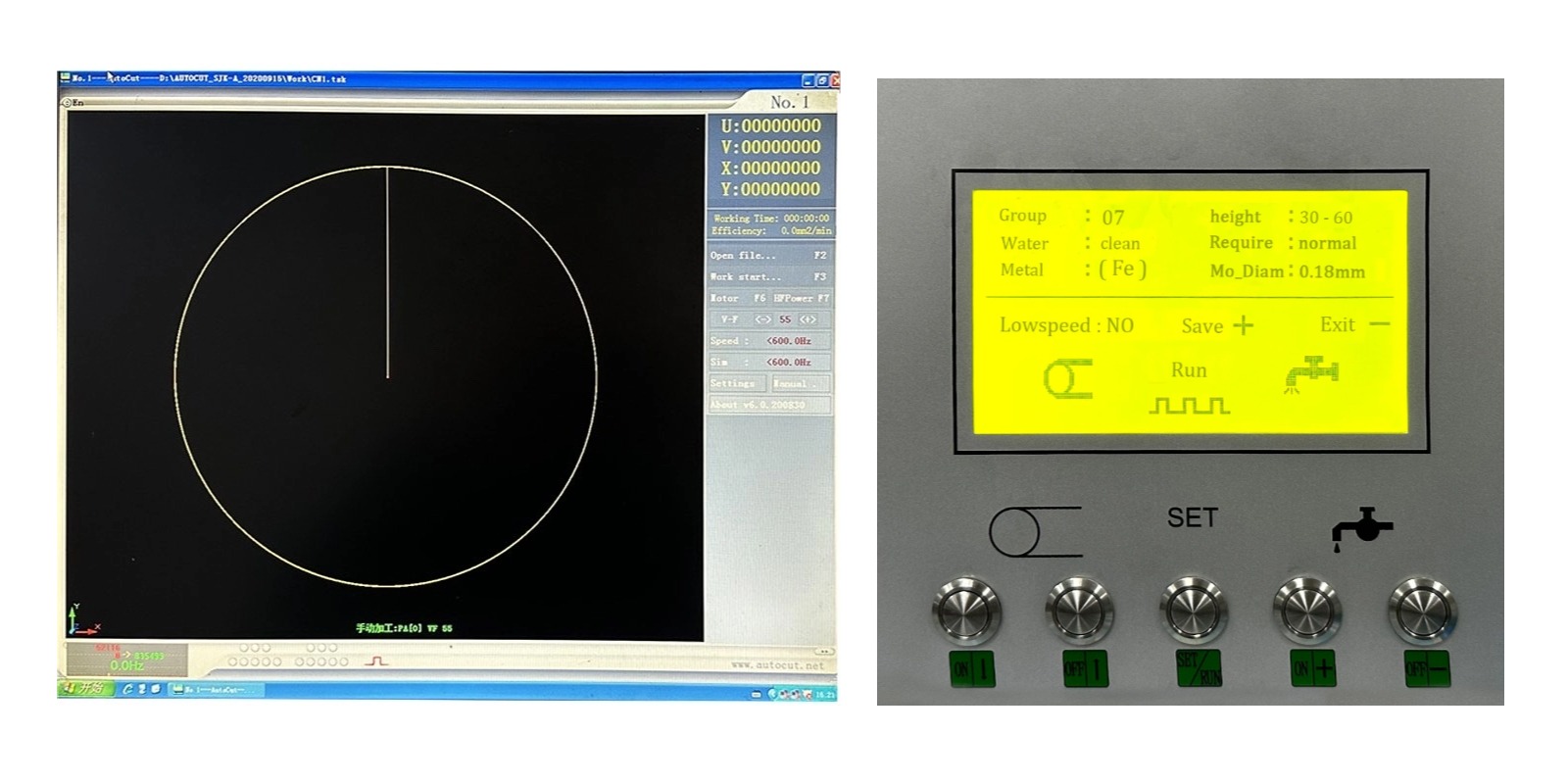

Control system | Autocut | Autocut | Autocut | Autocut | Autocut | Autocut | |

Tanker | L | 100 | 100 | 100 | 100 | 100 | 100 |

Filter type | 2nd filtration | 2nd filtration | 2nd filtration | 2nd filtration | 2nd filtration | 2nd filtration | |

Min. Moving unit | mm | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

Molybdenum wire tensioning device | √ | √ | √ | √ | √ | √ | |

Table waterproof cover | √ | √ | √ | √ | √ | √ | |

DRO | √ | √ | √ | √ | √ | √ |

Question: Are you a manufacturer or a distributor?

Answer: First of all, please match the worktable stroke and cutting thickness according to the size of the workpiece to find the appropriate model.

Secondly, please check whether the accuracy and roughness meet your requirements;Our MY-G series machines have higher precision and better surface finish.

Address

Tel

website

We will contact you within 24 hours. ( WhatsApp/facebook:)